Owned by OÜ Estanc, an Estonian industrial company with 30+ years of expertise in process equipment, H2Adsorb brings industrial know-how and innovation together.

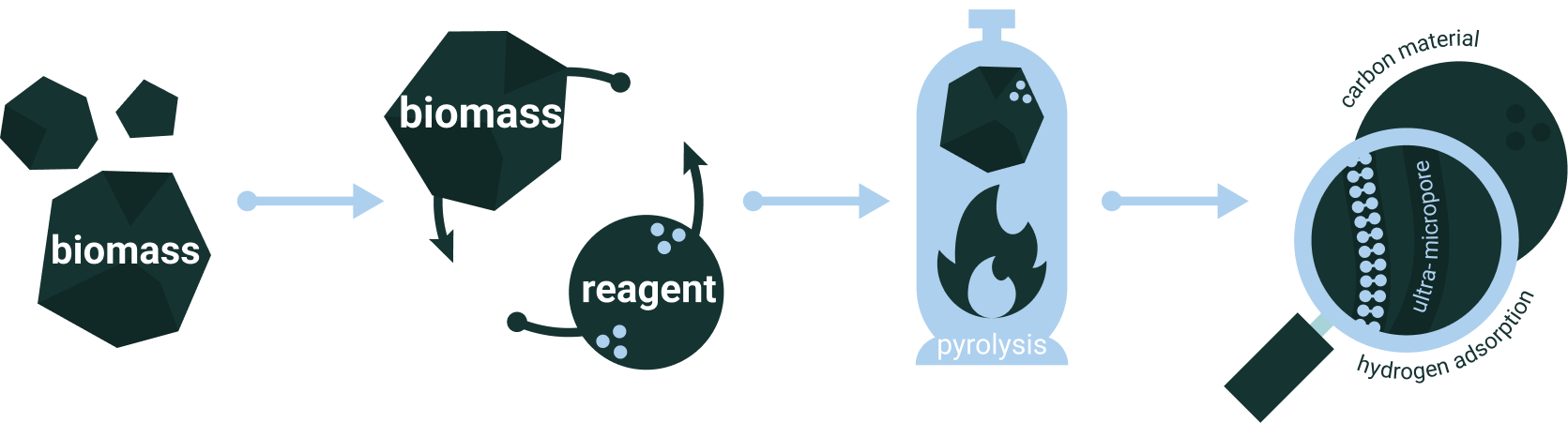

We are pioneering biomass-based adsorption technology to safely and efficiently store hydrogen. Our porous carbon adsorbents capture and release hydrogen molecules reversibly, enabling operation at low pressure (30–40 bar) and moderate cooling (–80 °C) while achieving storage densities comparable to compressed or liquid hydrogen.

H2Adsorb is redefining hydrogen storage through biomass-based adsorption technologies, delivering safe, efficient, and scalable energy solutions for a sustainable future.

Developed through a collaborative effort between Estanc OÜ and the University of Tartu, combining industrial expertise with academic research.

We store hydrogen in porous carbon adsorbents that capture and release molecules reversibly.

System operates at low pressure (30–40 bar) and moderate cooling (–80 °C).

Approaching compressed-gas levels at far lower pressures

Enables safe, cost-efficient, modular storage from 250 to 1000 kg modules.

Energy storage in residential and mixed-use complexes, enabling integration of renewables and backup power.

Mid-scale users such as hydrogen fueling stations or industrial facilities, and direct integration with electrolyzers for on-site production.

Larger industrial operations and energy hubs requiring reliable and scalable hydrogen supply.

CEO

CFO

Process Engineer

CTO, The University of Tartu

Mechanical Engineer

Cooling Engineer

Marketing

Advisor

Advisor

keeps the investments and operating cost low

comparable with high pressure storage tanks

compared to same pressure conventional gaseous tank

The energy transition hinges on clean hydrogen — but storage remains the weakest link. Current options (salt caverns, high-pressure tanks) are geographically limited, costly, or inflexible.

H2Adsorb delivers modular, low-cost, non-geological hydrogen storage for both seasonal energy balancing and flexible industrial use.

Standard modules: 250 kg, 500 kg, and 1000 kg.

Stackable design allows larger capacities.

Custom sizing is possible — limited mainly by pressure vessel design, manufacturing, and transport.

Targeting ~€0.05/kWh at 30-40 bar and -80C when directly coupled to an electrolyzer (no extra compression).

Yes – it is suitable for long-term storage, for example storing hydrogen produced in summer until winter. The fixed energy use is about 500 kWh per 1000 kg module.

No consumables are required. Only annual checks are needed for pressure vessel safety and the cooling system.

The system is designed according to PED and EN13445 standards. All risks are evaluated and mitigated through safety systems. In case of failure, controlled depressurization protocols are applied.

No – the fire load of our system is very low. Unlike gasoline or diesel, hydrogen does not create massive fires and disperses quickly. This makes H2Adsorb significantly safer than hydrocarbon fuels.

Yes – microporous carbon can be restored through a cleaning process.

Process: vacuum + heating to around 100 °C.

No need to replace the synthesized carbon entirely.

Laboratory results show no observed limitations on loading or unloading.

The ideal operating range is still under validation.

Exact performance figures are not yet public.